The flue gas purification project of the Hongmiaoling household waste incineration power generation project in Fuzhou City, Fujian Province, undertaken by Huaxing Oriental, has passed 72+24 hour trial operation

May 15, 2023, to expand the scope of the company's products and meet the needs of developing market, Chairman and Vice General Manager / Chief Engineer of Jiangsu Huaxing-east went to Japan to develop international sales of low-temperature catalysts, technical cooperation for De-dioxin / De-NOx bag filters (HBF), and technical cooperation for small-scale incineration and sludge incineration.

May 16, 2023, accompanied by executives from China headquarter of Mitsubishi Heavy Industries Environmental & Chemical Engineering (referred to as MHI Environment China), Chairman and Deputy General Manager / Chief Engineer of Jiangsu Huaxing-east visited MHI Environment in Yokohama, Japan. The delegation discussed the international sales of low-temp. catalysts, catalyst regeneration technology, and the international market prospects and cooperation methods of HBF (High-efficiency Bag Filter) with MHI Environment. Both parties conducted in-depth exchanges on technical cooperation in small-scale incineration and sludge incineration. The president and executives of MHI Environment reached a preliminary agreement with China deligation on midyear visiting and inspection to Huaxing-east as return.

MHI Environment:

President & CEO

Director / Executive Vice President / COO

General Manager / International Project Manager

International Operation & Maintenance Manager

International Business Manager

Mechanical Engineer / Furnace, boiler, FGT Designer

Mechanical Engineering Division Manager

MHI Environment China: General Manager and executives

Jiangsu Huaxing-east: Chairman and Deputy General Manager / Chief Engineer

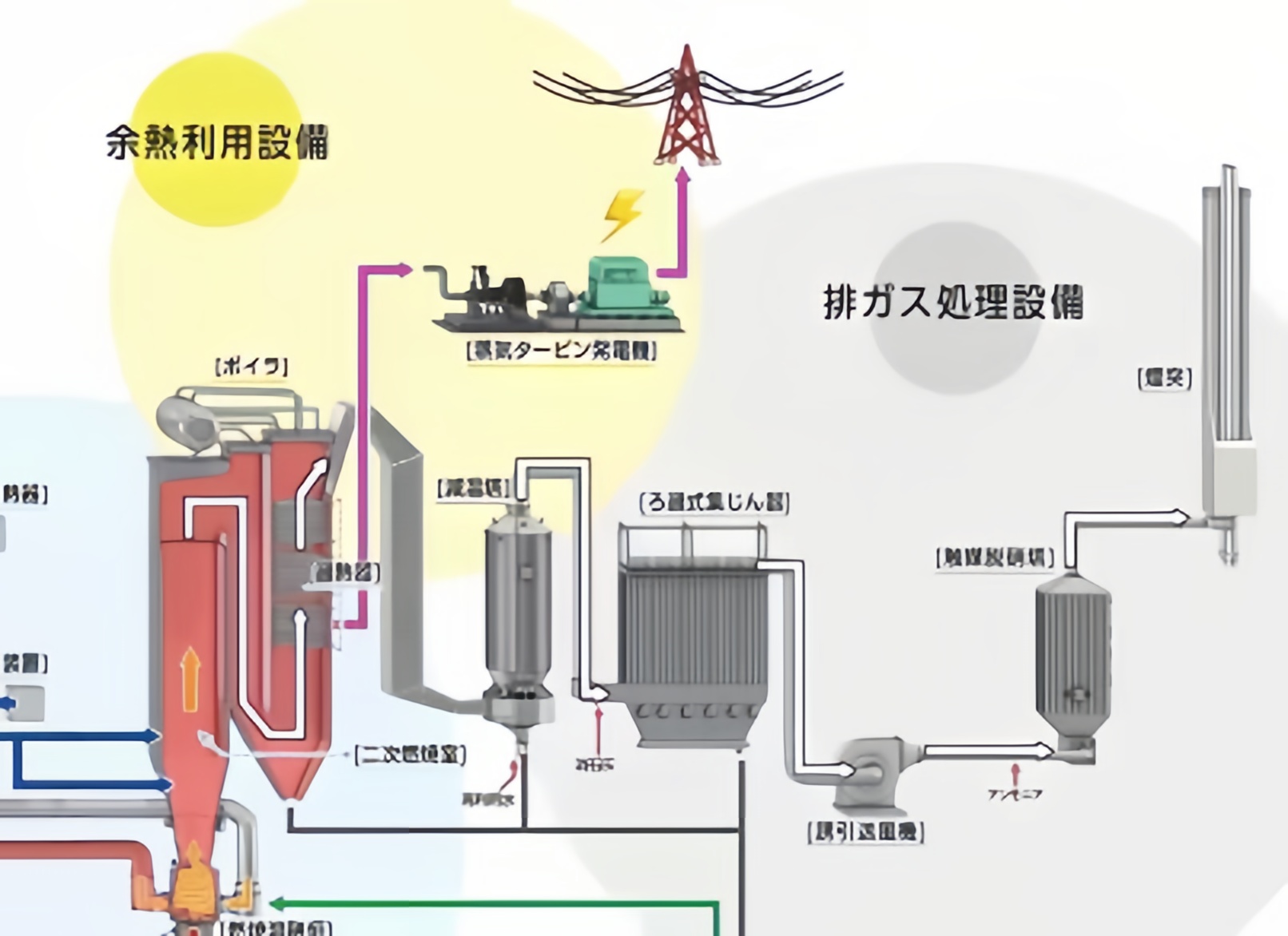

May 18, 2023, an inspection was conducted at MHI Environment's Factory (2×75 t/d incinerator). The FGT process flows as desuperheating tower , slaked lime injection, HBF, ID fan, SCR, and stack. Dioxin will be tested 4 times a year and data to be recorded.

(Reference: http://yamagata-eco.co.jp/facility)

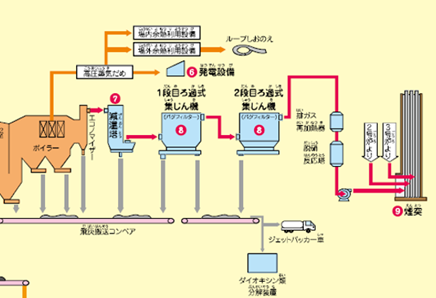

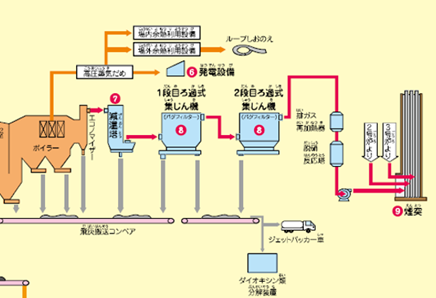

May 19, 2023, inspection of Hitachi Zosen's A factory (3×100 t/d incinerator). The FGT process flows as desuperheating tower, slaked lime injection, primary bag filter, secondary bag filter, SGH, SCR, ID fan, and stack. Denitrification reaction temperature ranges from 220 to 250 degrees Celsius.

In 2016, Huaxing reached a technology transfer agreement with Mitsubishi Heavy Industries (MHI) of Japan, which authorized the transfer of advanced ultra-clean emission technology of flue gas cleaning (FGC) to Huaxing. As a leading company in the field of waste incineration in the world, MHI owns advanced FGC technologies, such as single-tower dual-cycle wet scrubbing, low-temperature flue gas denitration, catalyst offline regeneration, as well as relevant engineering experiences. Huaxing has successively introduced the production and manufacturing technology of MHI's wet scrubbing, low-temperature SCR denitration, third-generation low-temperature denitration catalyst ( Exclusive license in China ), and catalyst offline regeneration ( Exclusive license in China ). These technologies are mainly applicable to flue gas generated by municipal waste, hazardous waste, and sludge incineration.

Mitsubishi Heavy Industries Environment · Chemical Engineering Co., Ltd. Visiting and Meeting(2017)

The catalyst imported from Mitsubishi Heavy Industries also have market references in many leading plants in China, such as Shanghai Laogang Phase II, Shenzhen East, Beijing Shunyi, Wuhan Qianzishan Phase I, etc. In addition to the cooperation with Mitsubishi Heavy Industries in the technology transformation, Huaxing also acts as the exclusive licensee of Mitsubishi Heavy Industries in China to sell the imported catalysts.

For more information, please click or scan below!

Follow us!