- Home

- About us

- News & Events

- Corporate business

- Engineering performance

- Contact us

- National regulations

-

National service hotline400-117-5858

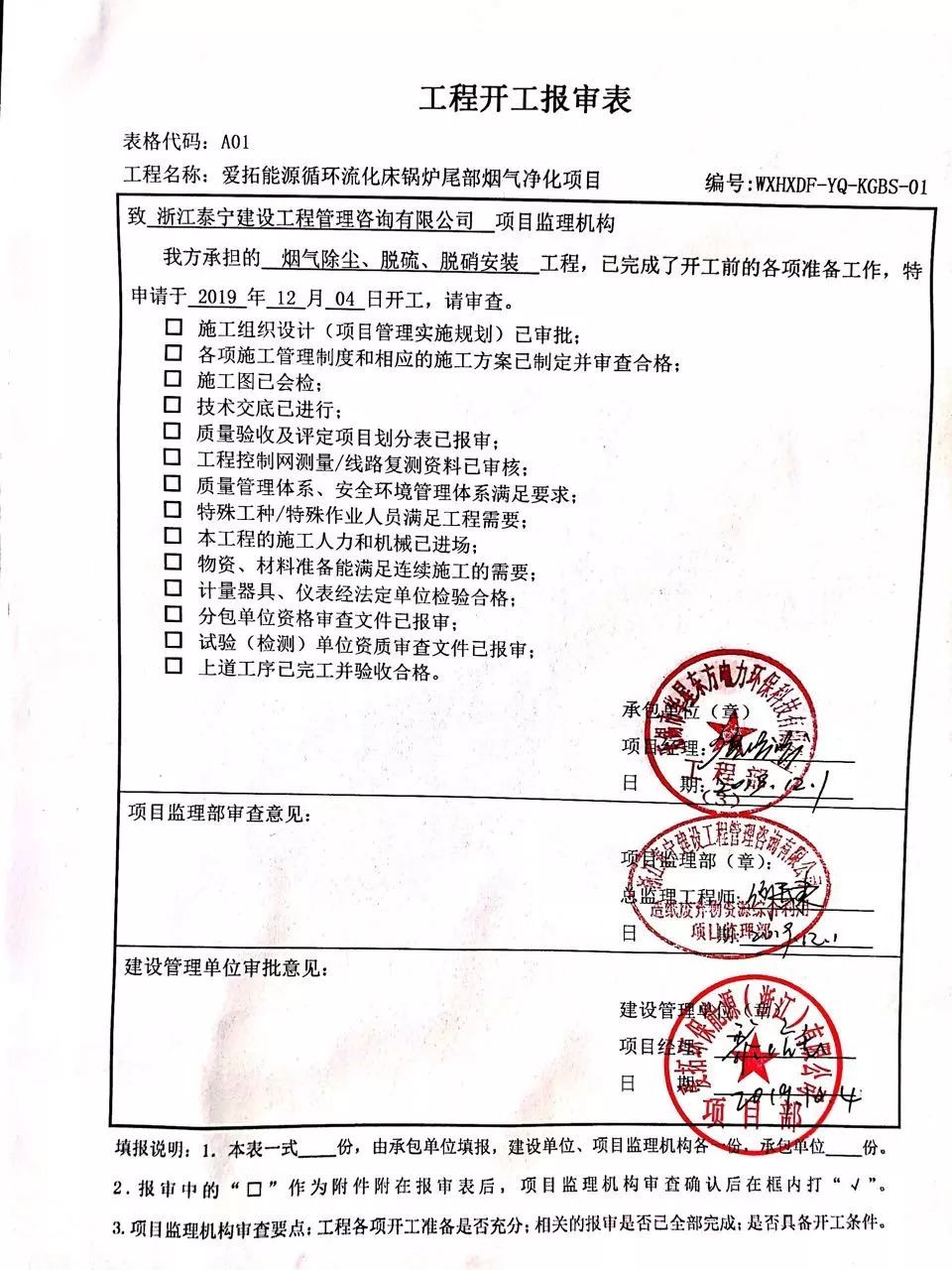

The flue gas cleaning system for the paper-making waste resource comprehensive utilization project of Aituo Environmental Protection Energy Co.,Ltd in Zhejiang Province was started its construction officially on December 4, 2019. Having become the world’s largest solid waste process project for single incinerator so far, this project has an epoch-making significance in the related industry. Its single-incinerator treatment capacity is at least 25 percent higher than that of the Malar Waste Incineration Plant in Sweden which is thought as the one having the highest single-incinerator treatment capcity in Europe.

Overall Effect Drawing of the Project

This project uses the boilers of Valmet,Finland. Its flue gas cleaning project is contracted by us in the form of EPC and Niro Company of Denmark was invited to jointly design with us for this project. Different from the current projects adopting the stereotyped designing process in China and based on the specific marginal conditions in this project, Huaxing East and Niro Company jointly designed the most suitable flue gas cleaning process for this project. Both the engineers from Niro headed by the Chief Engineer Clause and the engineers from HXET worked together to complete the process design and data verification for the project.

After they paid multiple visits to Europe where they had received the relevant professional trainings and finished their engineering practices of the similar process in the projects of Tianjing(Qingguang)Municipality City, Zhangye City as well as the projects of Gaomi City in Shangdong Province, the technical staff of HXET cooperated with Niro to complete the constructions of the first & second- stage projects of 1x1000TPD in Linzi City. After so many times projects cooperation, HXET and Niro cooperated again in the Aituo Environmental Protection Energy Project. With the completion and commissioning of this project which represents the top level in the solid waste industry , this project really contributes to the valuable experience accumulation for engineering practice which can help further promote the flue gas treatment in solid waste industry.

Mr. Clause, Chief Engineer of Niro, Denmark, along with his team was exchanging design ideas with the HXET technical team.

This project newly built a waste incinerator of 1×2000TPD and a steam turbine generator set of 1×N50MW. Its flue gas treatment adopts the combined processes of SNCR + Limestone Injection Deacidification Inside the Incinerator + ESP Dust Removal + SDA + Slaked Lime Dry Method Injection + Sodium Bicarbonate Injection + Activated Carbon Injection + BHF + Reserved Low Temperature SCR + Fly Ash Transportation, Storage and Stabilization. It is our company’s EPC Project.

Some new design ideas made in this project are listed as follows:When the FGC process was being designed, an ESP Pre-dedusting was added in order to control the flue gas treatment cost. After the production, the fly ash identification was introduced to reduce the fly ash treatment cost as well. When the removal efficiency of pre-dusting was set, the influence of fly ash removal efficiency on the flue gas operation dew point of the downstream equipment was fully considered.When the model of control atomizer was selected, the operational ratios of Semi-dry Method and Dry Method under different operating conditions were also considered,which can effectively avoid the problems like: the size of atomizer chosen is too large or it is difficult for the staff to operate. When the ESP was designed, a substantial alterations were made based on the feedback from the engineering experiences of the operated ESP used in the solid waste field such as the projects of Zhangye City and Gaomi City. Its design fully considered the feature of flue gas which contains higher chlorine and the working conditions of poor fly ash characteristics prevailing in the solid waste industry. Its design also benefits from some of the optimized designs of ESP operated in Amager Bakke Incineration Plant, Denmark.

At present, Huaxing East is stepping up its effort to construct this project. As one of the key projects of HXET in 2020, this project can help accumulate the precious FGC engineering data of big-sized incinerators for the industry and more engineering experience for Chinese enterprises engaged in the flue gas cleaning industry of solid waste to compete internationally, just like what the projects in progress by HXET such as Songjiang Second-stage 2x850TPD, Shanghai Municipality and Dengshuang 2x880TPD,Chengdu Municipality,3x880TPD in Nanchang Municipality, Second-state 1x1000TPD, Baoding City,2x1000TDP,Sanhe City did as before.